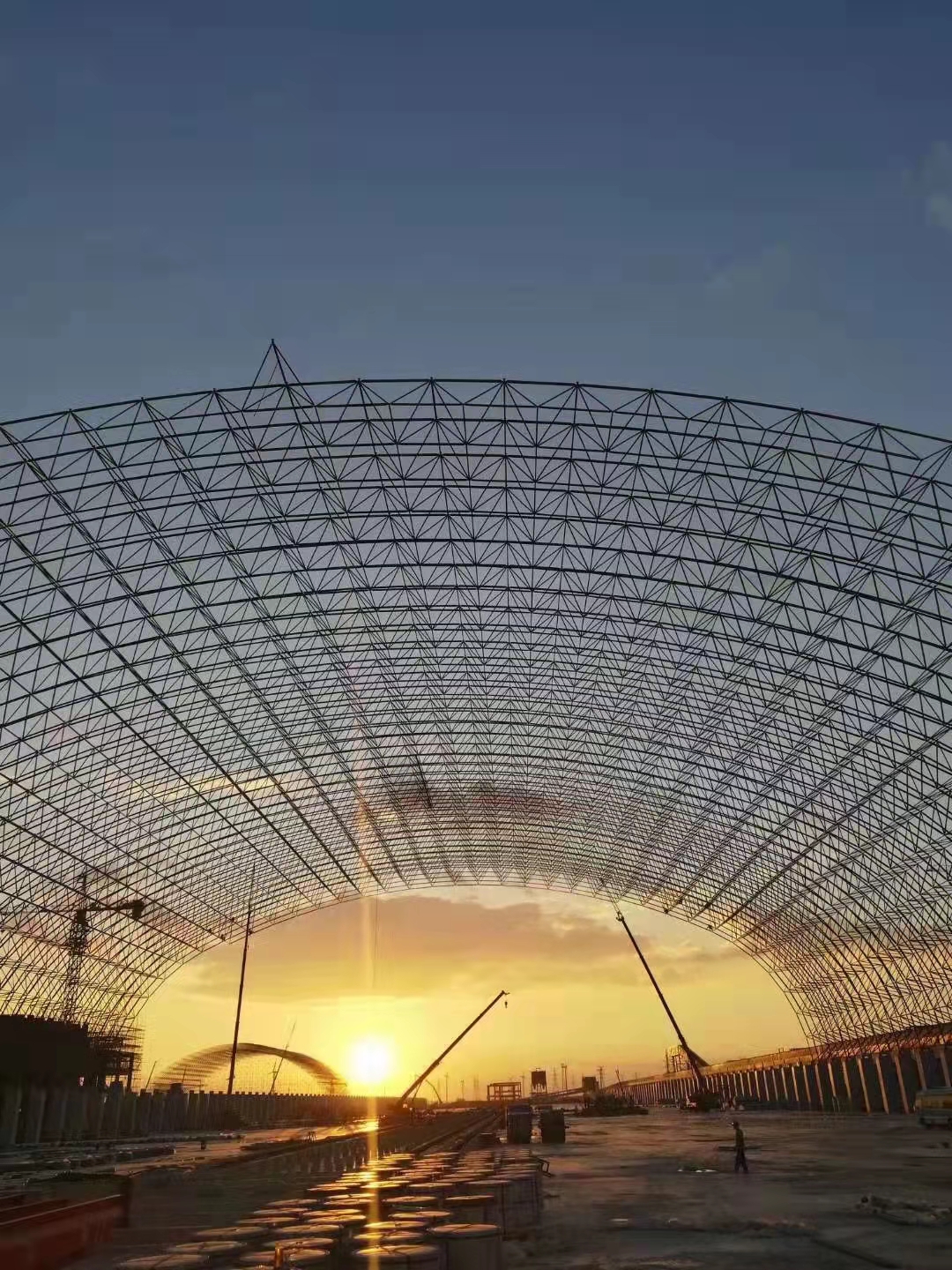

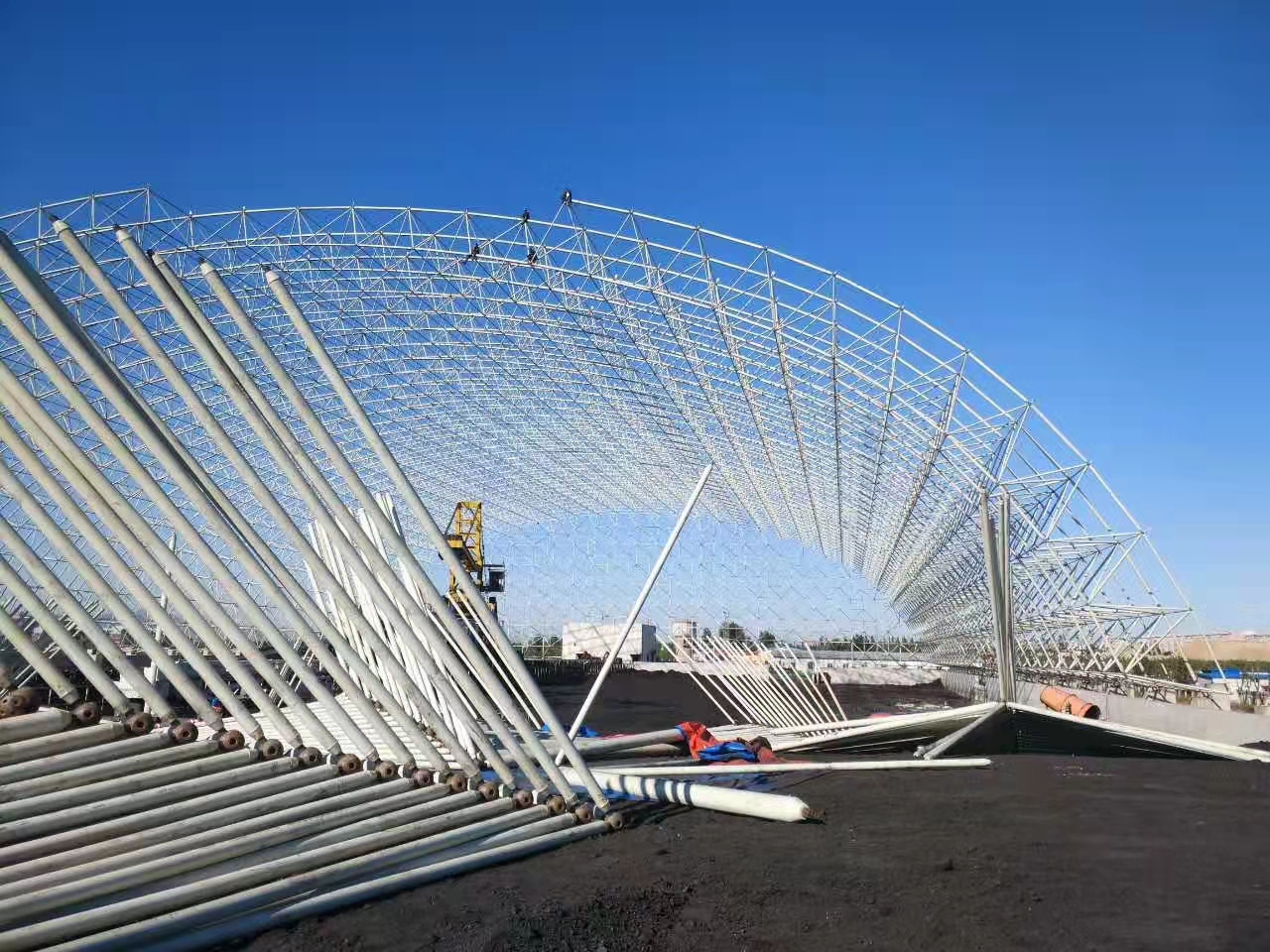

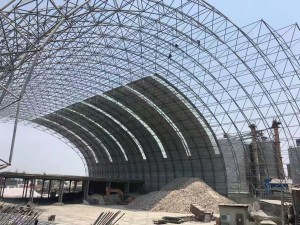

Ordos thermal power plant semi-circular steel structure space frame

Izinto eziluhlaza Q235B umbhobho odityanisiweyo / Ubude bubonke buziimitha ezingama-49 / Ubude obupheleleyo bungama-96 eemitha / Ubude bubonke bungama-567 eemitha.

1. Ukukhethwa kwezinto eziphathekayo kufuneka kusekelwe kwizatifikethi zomgangatho we-discretionary kunye neengxelo zokuphinda zihlolwe, ngokuhambelana nemigangatho kazwelonke yangoku.

2. Umbhobho wensimbi uthatha i-Q355B yensimbi, ipayipi yensimbi engenamthungo okanye ipayipi ephakamileyo edibeneyo (GB / T 700).

3. Iibholiti eziphakamileyo zenziwe nge-40Cr zicinywe kwaye zifudumeze kwaye ziphathwe ngokushushu ngokwe "Technical Conditions for High-Quality Carbon Structural Steel Structures" GB/T 16939. Ukusebenza kobubanzi

4. Iibhola zetsimbi zenziwe nge-Nombolo ye-45 ye-forgings yensimbi ehambelana ne-"Technical Conditions for High-Quality Carbon Structural Steel" GB 699, kunye namandla okuvelisa i-360N / mm2.

5. Ipleyiti yokutywina yentloko ye-cone yenziwe ngentsimbi ye-Q355B, kwaye intloko ye-cone yenziwe nge-forgings.

6. I-nut engenamsonto yenziwe nge-Q355B i-forgings yensimbi.Xa ububanzi beebholiti eziphezulu eziphezulu> M30, sebenzisa i-45-gauge forgings steel forgings.

7. Izikhonkwane zokuqinisa zenziwe nge-40Cr eziye zacinywa kwaye zavutha.

8. Inkxaso yenziwe ngentsimbi ye-Q355B, kwaye inkxaso yenziwe nge-Q235B yensimbi

9. I-electrode ithatha uchungechunge lwe-E43XX;Uthotho lwe-E50XX (yokuwelda kwebhola yebholiti kunye nombambo wokuthwala)

10. I-purlins zenziwe ngentsimbi ye-Q235B ye-C.

11. Iibholiti eziqhelekileyo zenziwe nge-Brock bolts yeBakala C eyenziwe ngentsimbi ye-Q235B ehlangabezana neemfuno zomgangatho welizwe langoku, kwaye ibakala lokusebenza ngu-4.8.

12. I-electrodes ye-welding kunye neengcingo ezisetyenziselwa i-welding kufuneka zihlangabezane neemfuno ezifanelekileyo zemigangatho yesizwe yangoku.Ukuwelda phakathi kweentsimbi ze-Q235B kwamkela i-E43 series electrode, kunye ne-welding phakathi kweentsimbi ze-Q345B zisebenzisa i-E50 series electrode.

13. Izinto zophahla: Jonga umzobo woyilo lwepaneli yophahla lwegridi ngeenkcukacha.

14. Ukongeza kokuhlangabezana neemfuno zenkcazo yezinto zelizwe, intsimbi esetyenziswe kule projekthi kufuneka ihlangabezane nezi mfuno zilandelayo:

a) Umlinganiselo wexabiso elilinganisiweyo lomlinganiselo wemveliso yentsimbi ukuya kwixabiso elilinganisiweyo lamandla obunzima akufanele libe ngaphezu kwe-0.85;

b) Intsimbi kufuneka ibe namanyathelo okuvelisa acacileyo, kwaye i-elongation kufuneka ibe ngaphezu kwe-20%;

c) Intsimbi kufuneka ibe ne-weldability elungileyo kunye nokuqina kwempembelelo efanelekileyo;