Inkqubo yeWelding yesakhelo sendawo yentsimbi

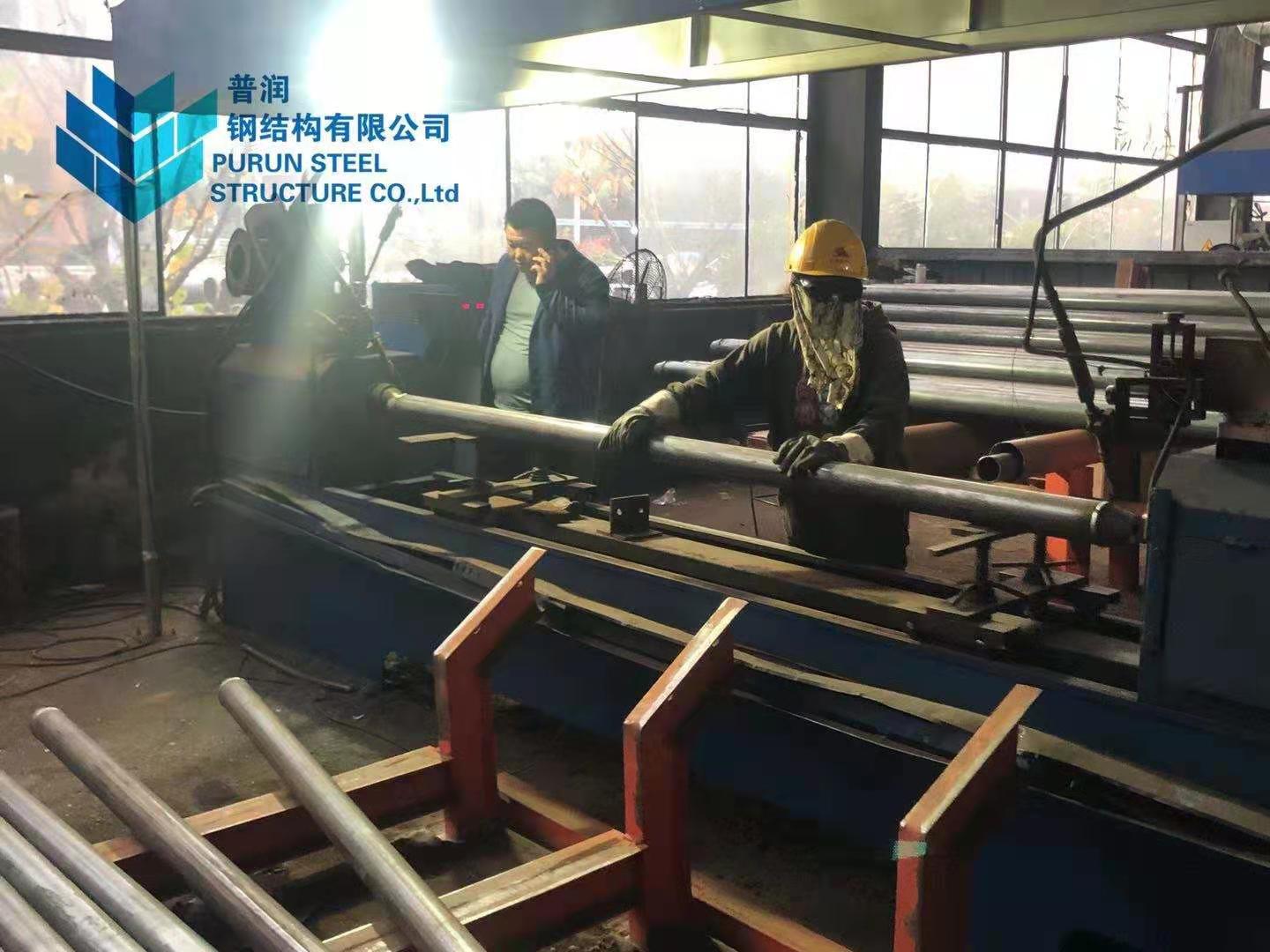

ukuwelda:

Inkqubo ye-welding yinkqubo ebalulekileyo ekuveliseni isakhelo sendawo yentsimbi, kwaye kufuneka iqhutywe ngokuhambelana ngokungqongqo nemiyalelo yokusebenza kwe-welding.Ukunciphisa uxinzelelo olushiyekileyo olubangelwa yi-welding, kwaye ulungise kwangexesha uguquko ngokufudumeza ilangatye.

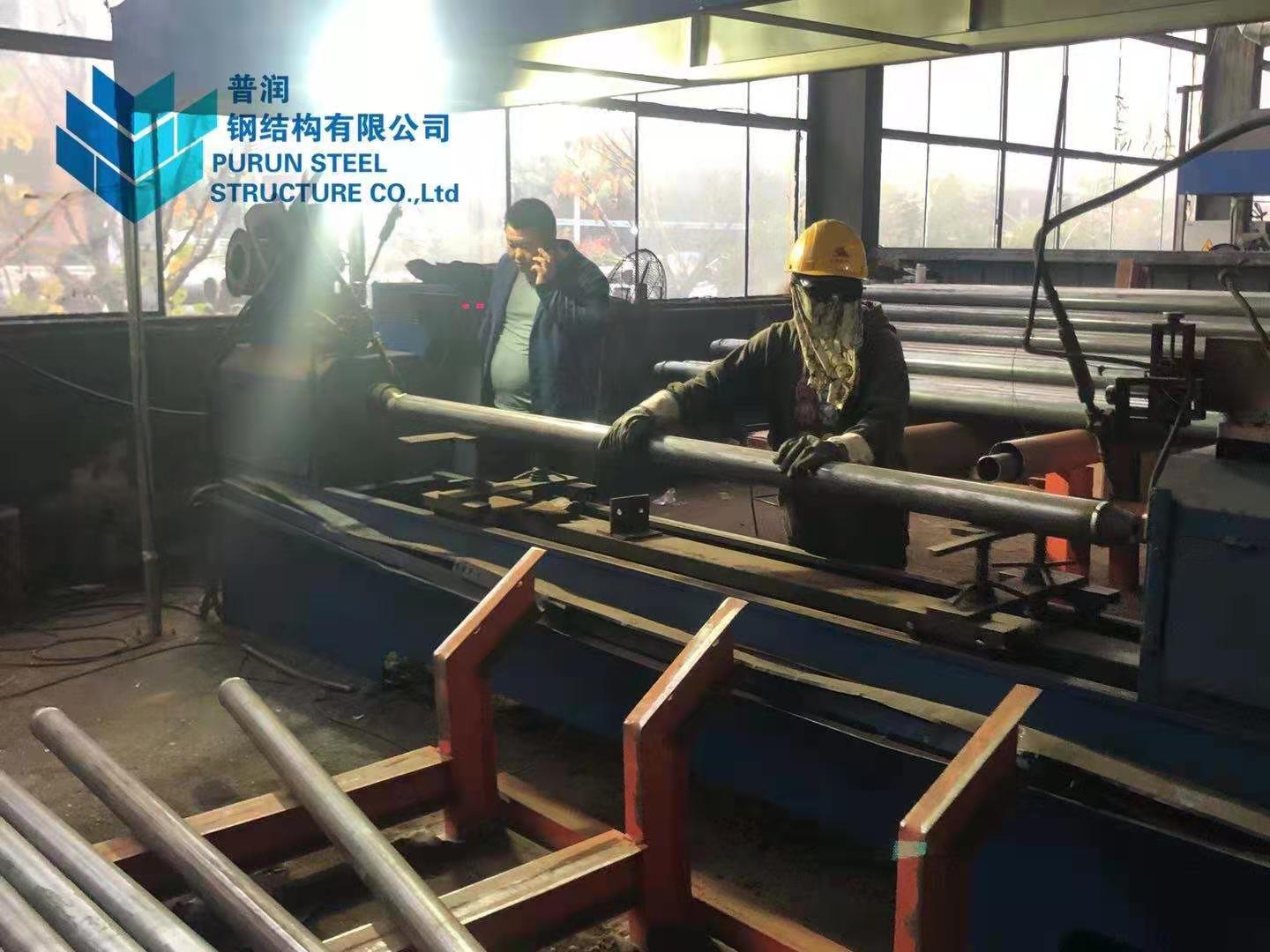

A. Xa umbhobho wentsimbi udityaniswe kunye nepleyiti yokutywina kunye nombhobho wentsimbi, i-groove iya kuvulwa ngokweemfuno, kwaye i-angle ye-groove iya kuhlangabezana neemfuno ze-engile eyenziwe phakathi kwe-electrode kunye ne-groove surface ukuze kuthintelwe ukuchithwa kunye nokudibanisa. ukubandakanywa kwe-slag.Ukongezelela, i-gap ye-groove kufuneka ibe nkulu ngokwaneleyo ukwenzela ukuba i-electrode arc ikwazi ukufikelela ngaphantsi kwe-groove kwaye igweme ubunzulu bokungena ngokwaneleyo.

B. Gwema ukubeka i-welding seam phakathi kwentonga xa umbhobho wensimbi uhlanjululwa.

C. Imiba efuna ingqwalasela kumsebenzi wokuwelda:

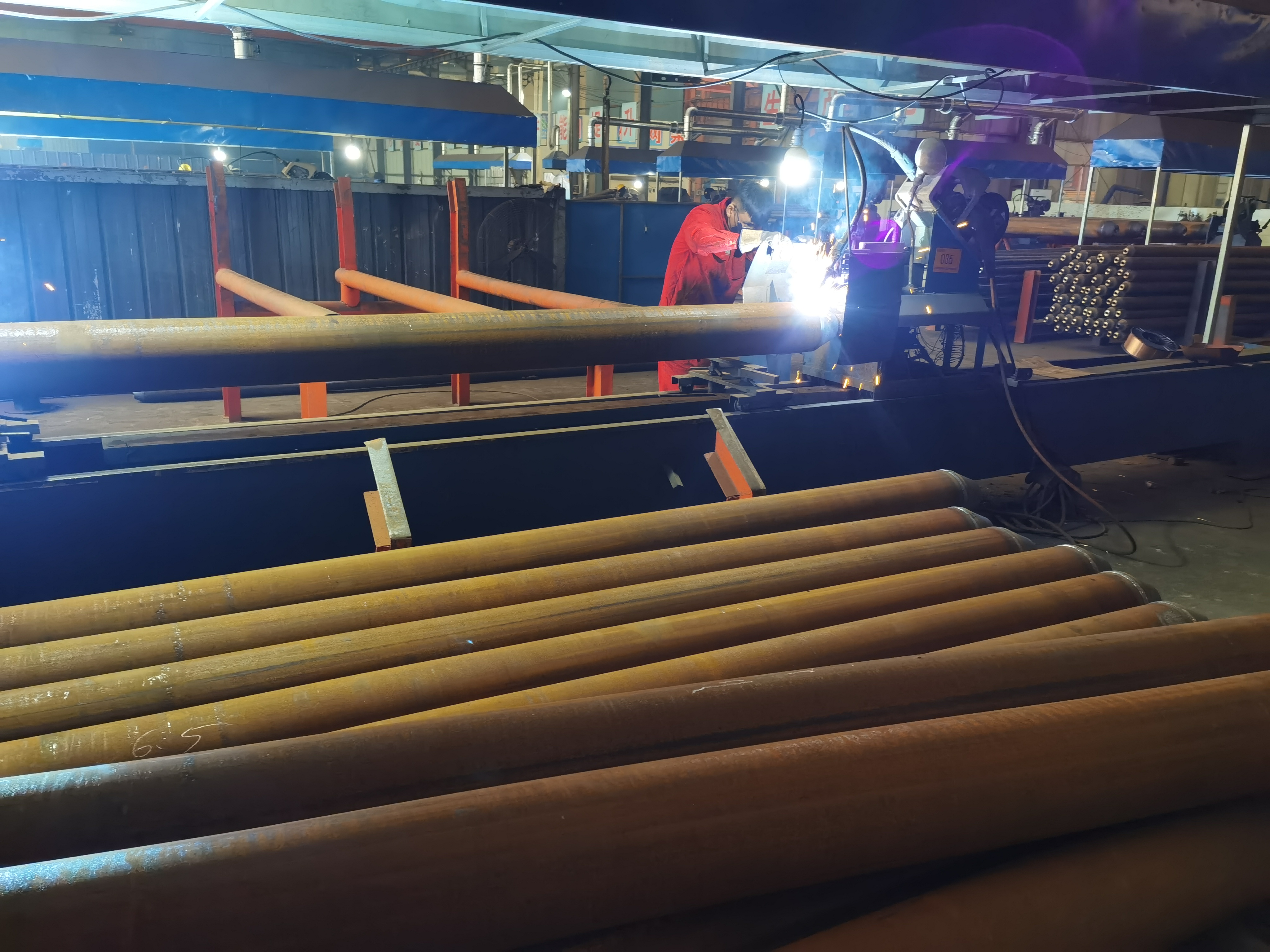

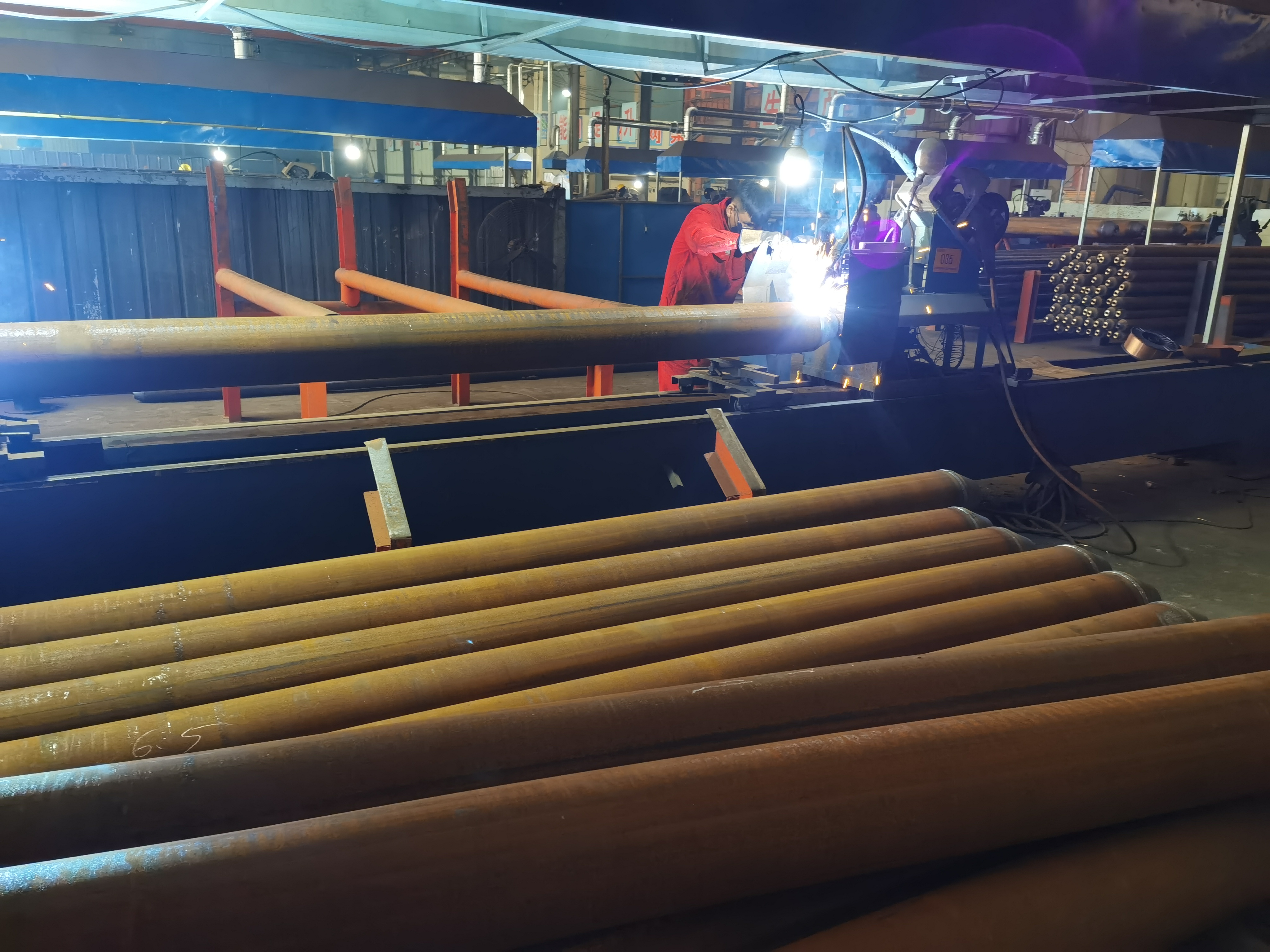

a.Ngexesha le-arc welding manual, uluhlu lokuhambisa akufanele lube lukhulu kakhulu, kwaye i-multi-pass kunye ne-multi-layer welding isetyenziswa.

Ngethuba lenkqubo, i-weld bead okanye i-interlayer welding slag, ukufakwa kwe-slag, i-oxide, njl. Kufuneka isuswe ngokuthe ngqo.Ivili lokugaya, intsimbi ingasetyenziswa.

Izixhobo ezifana neebrashi zocingo.

b.I-welding seam efanayo kufuneka idityaniswe ngokuqhubekayo kwaye igqitywe ngexesha elinye.

c.Kwimidibaniso eyahlukeneyo ye-weld, emva kokuba i-welding igqityiwe, i-slag kunye ne-spatter yensimbi ebusweni be-weld kufuneka ihlambuluke.

Jonga umgangatho wembonakalo ye-weld, kwaye akufuneki kubekho uxinzelelo, i-weld bead, i-undercut, i-blowhole, ukungabikho kwe-fusion, i-crack.

kunye nezinye iziphene zikhona.

d.Emva kokuba i-butt weld idityanisiwe, ukubonwa kwe-ultrasonic flaw kufuneka kuqhutywe emva kweeyure ezingama-24.